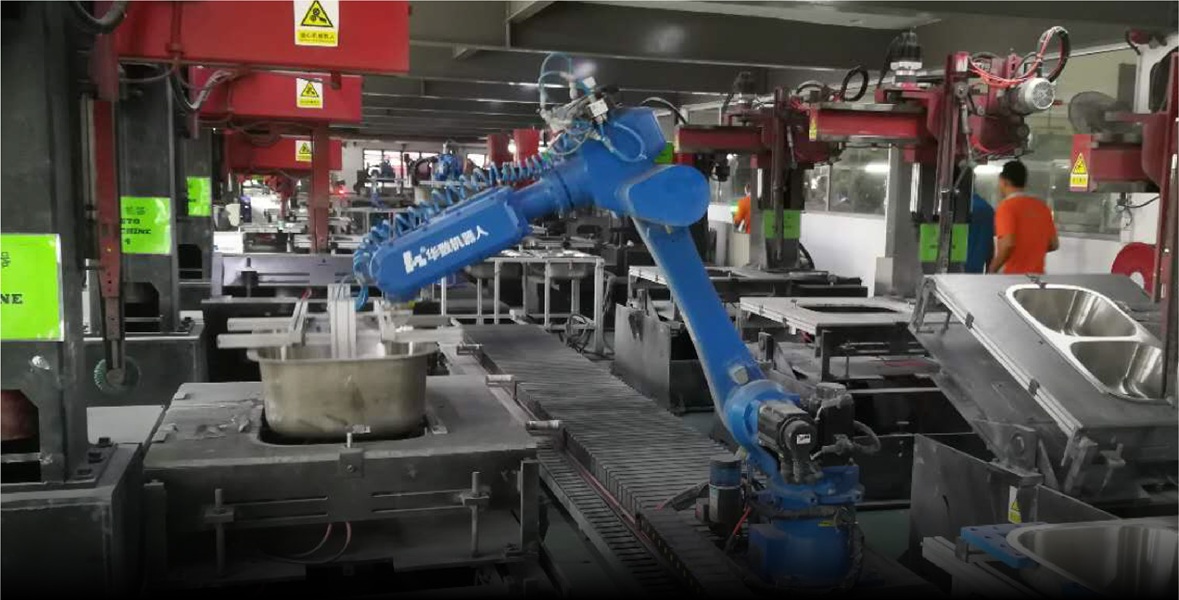

We're proud to use third-generation automated machines, keeping us at the forefront of stainless steel sink manufacturing. These cutting-edge machines represent the latest technological advances in the industry, enabling us to produce high-quality sinks with exceptional efficiency. Our annual production capacity for stainless steel sinks now reaches 800,000 units.

Production Manager

John Loh

With these state-of-the-art systems, Symbolsink can effectively meet orders of all sizes, ensuring fast delivery times, high-quality products, and cost-saving benefits for our customers.

To schedule a factory visit or to learn more details about our sinks, please leave a message. We will respond within one working day.

Reach our team directly on WhatsApp.

Click to start a conversation and accelerate your inquiry.

×